This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these template messages)

|

A circular economy (also referred to as circularity or CE)[2] is a model of resource production and consumption in any economy that involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products for as long as possible.[3][4][5][6] The concept aims to tackle global challenges such as climate change, biodiversity loss, waste, and pollution by emphasizing the design-based implementation of the three base principles of the model. The three principles required for the transformation to a circular economy are: designing out waste and pollution; keeping products and materials in use, and regenerating natural systems.[7] CE is defined in contradistinction to the traditional linear economy.[8][9] The idea and concepts of a circular economy have been studied extensively in academia, business, and government over the past ten years. It has been gaining popularity because it can help to minimize carbon emissions and the consumption of raw materials, open up new market prospects, and, principally, increase the sustainability of consumption.[10][11]

At a government level, a circular economy is viewed as a method of combating global warming, as well as a facilitator of long-term growth.[12] CE may geographically connect actors and resources to stop material loops at the regional level.[13] In its core principle, the European Parliament defines CE as "a model of production and consumption that involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products as long as possible. In this way, the life cycle of products is extended."[4] Global implementation of circular economy can reduce global emissions by 22.8 billion tons, 39% of global emissions in the year 2019.[14] By implementing circular economy strategies in five sectors alone: cement, aluminum, steel, plastics, and food 9.3 billion metric tons of CO2 equivalent (equal to all current emissions from transportation), can be reduced.[15][16][17]

In a circular economy, business models play a crucial role in enabling the shift from linear to circular processes. Various business models have been identified that support circularity, including product-as-a-service, sharing platforms, and product life extension models, among others.[18] These models aim to optimize resource utilization, reduce waste, and create value for businesses and customers alike, while contributing to the overall goals of the circular economy.

Definition edit

There are many definitions of the circular economy.[19] In China, CE is promoted as a top-down national political objective, while in other areas such as the European Union, Japan, and the USA, it is a tool to design bottom-up environmental and waste management policies. The ultimate goal of promoting CE is the decoupling of environmental pressure from economic growth.[20] A comprehensive definition could be: "Circular economy is an economic system that targets zero waste and pollution throughout materials lifecycles, from environment extraction to industrial transformation, and final consumers, applying to all involved ecosystems. Upon its lifetime end, materials return to either an industrial process or, in the case of a treated organic residual, safely back to the environment as in a natural regenerating cycle. It operates by creating value at the macro, meso, and micro levels and exploiting to the fullest the sustainability nested concept. Used energy sources are clean and renewable. Resource use and consumption are efficient. Government agencies and responsible consumers play an active role in ensuring the correct system long-term operation."[21]

More generally, circular development is a model of economic, social, and environmental production and consumption that aims to build an autonomous and sustainable society in tune with the issue of environmental resources.[22] The circular economy aims to transform our economy into one that is regenerative. An economy that innovates to reduce waste and the ecological and environmental impact of industries prior to happening, rather than waiting to address the consequences of these issues.[23] This is done by designing new processes and solutions for the optimization of resources, decoupling reliance on finite resources.[22]

The circular economy is a framework of three principles, driven by design: eliminating waste and pollution, keeping products and materials in use, and regenerating natural systems.[8] It is based increasingly on renewable energy and materials, and it is accelerated by digital innovation. It is a resilient, distributed, diverse, and inclusive economic model. The circular economy is an economic concept often linked to sustainable development, provision of the Sustainable Development Goals (Global Development Goals), and an extension of a green economy.[citation needed]

Other definitions and precise thresholds that separate linear from circular activity have also been developed in the economic literature.[24][19][20]

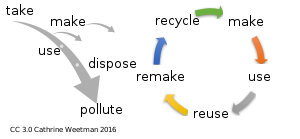

In a linear economy, natural resources are turned into products that are ultimately destined to become waste because of the way they have been designed and manufactured. This process is often summarized as "take, make, waste."[25] By contrast, a circular economy aims to transition from a 'take-make-waste' approach to a more restorative and regenerative system. It employs reuse, sharing, repair, refurbishment, remanufacturing and recycling to create a closed-loop system, reducing the use of resource inputs and the creation of waste, pollution, and carbon emissions.[26] The circular economy aims to keep products, materials, equipment, and infrastructure[27] in use for longer, thus improving the productivity of these resources. Waste materials and energy should become input for other processes through waste valorization: either as a component for another industrial process or as regenerative resources for nature (e.g., compost). The Ellen MacArthur Foundation (EMF) defines the circular economy as an industrial economy that is restorative or regenerative by value and design.[28][29]

Circular economy strategies can be applied at various scales, from individual products and services to entire industries and cities. For example, industrial symbiosis is a strategy where waste from one industry becomes an input for another, creating a network of resource exchange and reducing waste, pollution, and resource consumption.[30] Similarly, circular cities aim to integrate circular principles into urban planning and development, foster local resource loops, and promote sustainable lifestyles among their citizens.[31] Less than 10% of economic activity worldwide in 2022 and 2023 is circular.[16][32] Every year, the global population uses approximately 100 billion tonnes of materials, with more than 90% of them being wasted. The circular economy seeks to address this by eliminating waste entirely.[33]

History and aims edit

The concept of a circular economy cannot be traced back to one single date or author, rather to different schools of thought.[34]

The concept of a circular economy can be linked to various schools of thought, including industrial ecology, biomimicry, and cradle-to-cradle design principles. Industrial ecology is the study of material and energy flows through industrial systems, which forms the basis of the circular economy. Biomimicry involves emulating nature's time-tested patterns and strategies in designing human systems. Cradle-to-cradle design is a holistic approach to designing products and systems that considers their entire life cycle, from raw material extraction to end-of-life disposal, and seeks to minimize waste and maximize resource efficiency. These interrelated concepts contribute to the development and implementation of the circular economy.[35]

General systems theory, founded by the biologist Ludwig von Bertalanffy, considers growth and energy for open and closed state systems. This theory was then applied to other areas, such as, in the case of the circular economy, economics.[citation needed] Economist Kenneth E. Boulding, in his paper "The Economics of the Coming Spaceship Earth," argued that a circular economic system is a prerequisite for the maintenance of the sustainability of human life on Earth.[36] Boulding describes the so-called "cowboy economy" as an open system in which the natural environment is typically perceived as limitless: no limit exists on the capacity of the outside to supply or receive energy and material flows.

Walter R. Stahel and Geneviève Reday-Mulvey, in their book "The Potential for Substituting Manpower for Energy," lay the foundation for the principles of the circular economy by describing how increasing labour may reduce energy intensive activities.

Simple economic models have ignored the economy-environment interrelationships. Allan Kneese in "The Economics of Natural Resources" indicates how resources are not endlessly renewable, and mentions the term circular economy for the first time explicitly in 1988.[37]

In their book Economics of Natural Resources and the Environment, Pearce and Turner explain the shift from the traditional linear or open-ended economic system to the circular economic system (Pearce and Turner, 1990).[38] They describe an economic system where waste at extraction, production, and consumption stages is turned into inputs.

In the early 2000s, China integrated the notion into its industrial and environmental policies to make them resource-oriented, production-oriented, waste-oriented, use-oriented, and life cycle-oriented.[39] The Ellen MacArthur Foundation [40] was instrumental in the diffusion of the concept in Europe and the Americas.[41]

In 2010, the concept of circular economy started to become popular internationally after the publication of several reports.[36]

The European Union introduced its vision of the circular economy in 2014, with a New Circular Economy Action Plan launched in 2020 that "shows the way to a climate-neutral, competitive economy of empowered consumers".[41]

The original diffusion of the notion benefited from three major events: the explosion of raw material prices between 2000 and 2010, the Chinese control of rare earth materials, and the 2008 economic crisis.[42] Today, the climate emergency and environmental challenges induce companies and individuals in rethink their production and consumption patterns. The circular economy is framed as one of the answers to these challenges. Key macro-arguments in favour of the circular economy are that it could enable economic growth that does not add to the burden on natural resource extraction but decouples resource uses from the development of economic welfare for a growing population, reduces foreign dependence on critical materials, lowers CO2 emissions, reduces waste production, and introduces new modes of production and consumption able to create further value.[4] Corporate arguments in favour of the circular economy are that it could secure the supply of raw materials, reduce the price volatility of inputs and control costs, reduce spills and waste, extend the life cycle of products, serve new segments of customers, and generate long-term shareholder value. A key idea behind the circular business models is to create loops throughout to recapture value that would otherwise be lost.[43]

Of particular concern is the irrevocable loss of raw materials due to their increase in entropy in the linear business model.[44] Starting with the production of waste in manufacturing, the entropy increases further by mixing and diluting materials in their manufacturing assembly, followed by corrosion and wear and tear during the usage period. At the end of the life cycle, there is an exponential increase in disorder arising from the mixing of materials in landfills.[44] As a result of this directionality of the entropy law, the world's resources are effectively "lost forever".[citation needed]

Circular development is directly linked to the circular economy and aims to build a sustainable society based on recyclable and renewable resources, to protect society from waste, and to be able to form a model that no longer considering resources as infinite.[22] This new model of economic development focuses on the production of goods and services, taking into account environmental and social costs.[22] Circular development, therefore, supports the circular economy to create new societies in line with new waste management and sustainability objectives that meet the needs of citizens. It is about enabling economies and societies, in general, to become more sustainable.[citation needed]

However, critiques of the circular economy[45] suggest that proponents of the circular economy may overstate the potential benefits of the circular economy. These critiques put forward the idea that the circular economy has too many definitions to be delimited, making it an umbrella concept that, although exciting and appealing, is hard to understand and assess. Critiques mean that the literature ignores much-established knowledge. In particular, it neglects the thermodynamic principle that one can neither create nor destroy matter. Therefore, a future where waste no longer exists, where material loops are closed, and products are recycled indefinitely is, in any practical sense, impossible. They point out that a lack of inclusion of indigenous discourses from the Global South means that the conversation is less eco-centric than it depicts itself. There is a lack of clarity as to whether the circular economy is more sustainable than the linear economy and what its social benefits might be, in particular, due to diffuse contours.[46] Other issues include the increasing risks of cascading failures which are a feature of highly interdependent systems, and have potential harm to the general public. When implemented in bad faith, touted "Circular Economy" activities can often be little more than reputation and impression management for public relations purposes by large corporations and other vested interests; constituting a new form of greenwashing. It may thus not be the panacea many had hoped for.[47]

Sustainability edit

Intuitively, the circular economy would appear to be more sustainable than the current linear economic system. Reducing the resources used and the waste and leakage created conserves resources and helps to reduce environmental pollution. However, it is argued by some that these assumptions are simplistic and that they disregard the complexity of existing systems and their potential trade-offs. For example, the social dimension of sustainability seems to be only marginally addressed in many publications on the circular economy. Some cases that might require different or additional strategies, like purchasing new, more energy-efficient equipment. By reviewing the literature, a team of researchers from Cambridge and TU Delft showed that there are at least eight different relationship types between sustainability and the circular economy.[26] In addition, it is important to underline the innovation aspect at the heart of sustained development based on circular economy components.[48]

Scope edit

The circular economy can have a broad scope. Researchers have focused on different areas such as industrial applications with both product-oriented and natural resources and services,[49] practices and policies[50] to better understand the limitations that the CE currently faces, strategic management for details of the circular economy and different outcomes such as potential re-use applications[51] and waste management.[52]

The circular economy includes products, infrastructure, equipment, and services[53] and applies to every industry sector. It includes 'technical' resources (metals, minerals, fossil resources) and 'biological' resources (food, fibres, timber, etc.).[29] Most schools of thought advocate a shift from fossil fuels to the use of renewable energy, and emphasize the role of diversity as a characteristic of resilient and sustainable systems. The circular economy includes a discussion of the role of money and finance as part of the wider debate, and some of its pioneers have called for a revamp of economic performance measurement tools.[54] One study points out how modularization could become a cornerstone to enabling a circular economy and enhancing the sustainability of energy infrastructure.[55] One example of a circular economy model is the implementation of renting models in traditional ownership areas (e.g., electronics, clothes, furniture, transportation). By renting the same product to several clients, manufacturers can increase revenues per unit, thus decreasing the need to produce more to increase revenues. Recycling initiatives are often described as circular economy and are likely to be the most widespread models.[54]

According to a report of the organization "Circle economy" global implementation of circular economy can reduce global emissions by 22.8 billion tons, 39% of global emissions in the year 2019.[14] By 2050, 9.3 billion metric tons ofCO2 equivalent, or almost half of the global greenhouse gas emissions from the production of goods, might be reduced by implementing circular economy strategies in only five significant industries: cement, aluminum, steel, plastics, and food. That would equal to eliminating all current emissions caused by transportation.[15][16][56]

Background edit

As early as 1966, Kenneth Boulding raised awareness of an "open economy" with unlimited input resources and output sinks, in contrast with a "closed economy," in which resources and sinks are tied and remain as long as possible part of the economy. Boulding's essay "The Economics of the Coming Spaceship Earth"[57] is often cited as the first expression of the "circular economy",[58] although Boulding does not use that phrase.[citation needed]

The circular economy is grounded in the study of feedback-rich (non-linear) systems, particularly living systems.[29] The contemporary understanding of the circular economy and its practical applications to economic systems has evolved, incorporating different features and contributions from a variety of concepts sharing the idea of closed loops. Some of the relevant theoretical influences are cradle to cradle, laws of ecology (e.g., Barry Commoner § The Closing Circle), looped and performance economy (Walter R. Stahel), regenerative design, industrial ecology, biomimicry and blue economy (see section "Related concepts").[26]

The circular economy was further modelled by British environmental economists David W. Pearce and R. Kerry Turner in 1989. In Economics of Natural Resources and the Environment,[59] they pointed out that a traditional open-ended economy was developed with no built-in tendency to recycle, which was reflected by treating the environment as a waste reservoir.[60]

In the early 1990s, Tim Jackson began to create the scientific basis for this new approach to industrial production in his edited collection Clean Production Strategies,[61] including chapters from preeminent writers in the field such as Walter R Stahel, Bill Rees and Robert Constanza. At the time still called 'preventive environmental management', his follow-on book Material Concerns: Pollution, Profit and Quality of Life[62] synthesized these findings into a manifesto for change, moving industrial production away from an extractive linear system towards a more circular economy.[citation needed]

Emergence of the idea edit

In their 1976 research report to the European Commission, "The Potential for Substituting Manpower for Energy," Walter Stahel and Genevieve Reday sketched the vision of an economy in loops (or a circular economy) and its impact on job creation, economic competitiveness, resource savings and waste prevention. The report was published in 1982 as the book Jobs for Tomorrow: The Potential for Substituting Manpower for Energy.[63]

In 1982, Walter Stahel was awarded third prize in the Mitchell Prize competition on sustainable business models with his paper, The Product-Life Factor. The first prize went to the then US Secretary of Agriculture, the second prize to Amory and Hunter Lovins, and fourth prize to Peter Senge.[citation needed]

Considered one of the first pragmatic and credible sustainability think tanks, the main goals of Stahel's institute are to extend the working life of products, to make goods last longer, to reuse existing goods, and ultimately to prevent waste. This model emphasizes the importance of selling services rather than products, an idea referred to as the "functional service economy" and sometimes put under the wider notion of "performance economy." This model also advocates "more localization of economic activity".[64]

Promoting a circular economy was identified as a national policy in China's 11th five-year plan starting in 2006.[65] The Ellen MacArthur Foundation has more recently outlined the economic opportunity of a circular economy, bringing together complementary schools of thought in an attempt to create a coherent framework, thus giving the concept a wide exposure and appeal.[66]

Most frequently described as a framework for thinking, its supporters claim it is a coherent model that has value as part of a response to the end of the era of cheap oil and materials and, moreover, contributes to the transition to a low-carbon economy. In line with this, a circular economy can contribute to meeting the COP 21 Paris Agreement. The emissions reduction commitments made by 195 countries at the COP 21 Paris Agreement are not sufficient to limit global warming to 1.5 °C. To reach the 1.5 °C ambition, it is estimated that additional emissions reductions of 15 billion tonnes of CO2 per year need to be achieved by 2030. Circle Economy and Ecofys estimated that circular economy strategies may deliver emissions reductions that could bridge the gap by half.[67]

Moving away from the linear model edit

Linear "take, make, dispose" industrial processes, and the lifestyles dependent on them, use up finite reserves to create products with a finite lifespan, which end up in landfills or in incinerators. The circular approach, by contrast, takes insights from living systems. It considers that our systems should work like organisms, processing nutrients that can be fed back into the cycle—whether biological or technical—hence the "closed loop" or "regenerative" terms usually associated with it. The generic circular economy label can be applied to or claimed by several different schools of thought, but all of them gravitate around the same basic principles.[citation needed]

One prominent thinker on the topic is Walter R. Stahel, an architect, economist, and founding father of industrial sustainability. Credited with having coined the expression "Cradle to Cradle" (in contrast with "Cradle to Grave," illustrating our "Resource to Waste" way of functioning), in the late 1970s, Stahel worked on developing a "closed loop" approach to production processes, co-founding the Product-Life Institute in Geneva. In the UK, Steve D. Parker researched waste as a resource in the UK agricultural sector in 1982, developing novel closed-loop production systems. These systems mimicked and worked with the biological ecosystems they exploited.[citation needed]

Cradle to Cradle edit

Circular economy often refers to quantities of recycled materials or reduced waste, however Cradle to Cradle Design focuses on quality of products including safety for humans and environmental health. Popularized by the book Cradle to Cradle: Remaking The Way We Make Things, Cradle to Cradle Design has been widely implemented by architect William McDonough, who was introduced as the "father of the circular economy" while receiving the 2017 Fortune Award for Circular Economy Leadership in Davos during the World Economic Forum.[citation needed]

Levels of circularity ("R" models) edit

In the 2010s, several models of a circular economy were developed that employed a set of steps, or levels of circularity, typically using English verbs or nouns starting with the letter "r".[68] The first such model, known as the "Three R principle", was "Reduce, Reuse, Recycle",[68] which can be traced back as early as the 1970s.[69] According to Breteler (2022), the 'most comprehensive and extensive' of four compared models was the "10R principle", developed by sustainable entrepreneurship professor and former Dutch Environment Minister Jacqueline Cramer.[68]

| 10R principle Cramer 2017[70] |

Ellen MacArthur Foundation 2013[71] |

Ladder of Lansink Lansink 2015[72] |

Three R principle (1970s) |

Explanation (Cramer 2017)[70][68] |

|---|---|---|---|---|

| Refuse | Maintain/prolong | Prevention | Reduce | 'Prevent raw materials use' |

| Reduce | 'Decrease raw materials use' | |||

| Renew/Redesign[73] | 'Redesign product in view of circularity' | |||

| Reuse | Reuse/redistribute | Reuse | Reuse | 'Use product again (second hand)' |

| Repair | 'Maintain and repair product' | |||

| Refurbish | Refurbish/ Remanufacture |

'Revive product' | ||

| Remanufacture | 'Make new product from second hand' | |||

| Repurpose | 'Re-use product but with other function' | |||

| Recycle | Recycle | Recycling | Recycle | 'Salvage material streams with highest possible value' |

| Recover | Energy recovery | Energy recovery | 'Incinerate waste with energy recovery' | |

| Incineration | ||||

| Landfill | Landfill |

Towards the circular economy edit

In 2013, a report was released entitled Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. The report, commissioned by the Ellen MacArthur Foundation and developed by McKinsey & Company, was the first volume of its kind[74][75] to consider the economic and business opportunity for the transition to a restorative, circular model. Using product case studies and economy-wide analysis, the report details the potential for significant benefits across the EU. It argues that a subset of the EU manufacturing sector could realize net materials cost savings worth up to $630 billion annually towards 2025—stimulating economic activity in the areas of product development, remanufacturing and refurbishment. Towards the Circular Economy also identified the key building blocks in making the transition to a circular economy, namely in skills in circular design and production, new business models, skills in building cascades and reverse cycles, and cross-cycle/cross-sector collaboration.[76] This is supported by a case study from the automotive industry,[77] highlighting the importance of integrating a circular model holistically within the entire value chain of a company, taking into account the interdependencies between the product, process, and system level.[citation needed]

Another report by WRAP and the Green Alliance (called "Employment and the circular economy: job creation in a more resource efficient Britain"), done in 2015 has examined different public policy scenarios to 2030. It estimates that, with no policy change, 200,000 new jobs will be created, reducing unemployment by 54,000. A more aggressive policy scenario could create 500,000 new jobs and permanently reduce unemployment by 102,000.[78] The International Labour Organization predicts that implementing a circular economy by 2030 might result in an additional 7-8 million jobs being created globally.[79][16] However, other research has also found that the adoption of circular economy principles may lead to job losses in emerging economies.[80]

On the other hand, implementing a circular economy in the United States has been presented by Ranta et al.[49] who analyzed the institutional drivers and barriers for the circular economy in different regions worldwide, by following the framework developed by Scott R.[81] In the article, different worldwide environment-friendly institutions were selected, and two types of manufacturing processes were chosen for the analysis (1) a product-oriented, and (2) a waste management.[49][81] Specifically, in the U.S., the product-oriented company case in the study was Dell, a US manufacturing company for computer technology, which was the first company to offer free recycling to customers and to launch to the market a computer made from recycling materials from a verified third-party source.[49] Moreover, the waste management case that includes many stages such as collection, disposal, recycling[82] in the study was Republic Services, the second-largest waste management company in the US. The approach to defining the drivers and barriers was to first identify indicators for their cases in study and then to categorize these indicators into drivers when the indicator was in favor of the circular economy model or a barrier when it was not.[49]

On 2 March 2022 in Nairobi, representatives of 175 countries pledged to create a legally binding agreement to end plastic pollution by the end of the year 2024. The agreement should address the full lifecycle of plastic and propose alternatives including reusability. The agreement is expected to facilitate the transition to a circular economy that will reduce GHG emissions by 25 percent, according to the published statement.[83][84]

Circular product design and standards edit

Product designs that optimize durability, ease of maintenance and repair, upgradability, re-manufacturability, separability, disassembly, and reassembly are considered key elements for the transition toward circularity of products.[85] Standardization can facilitate related "innovative, sustainable and competitive advantages for European businesses and consumers".[86] Design for standardization and compatibility would make "product parts and interfaces suitable for other products and aims at multi-functionality and modularity".[87] A "Product Family Approach" has been proposed to establish "commonality, compatibility, standardization, or modularization among different products or product lines".[88]

It has been argued that emerging technologies should be designed with circular economy principles from the start, including solar panels.[89]

Design of circularity processes edit

For sustainability and health, the circularity process designs may be of crucial importance. Large amounts of electronic waste are already recycled but far from where they were consumed, with often low efficiency, and with substantial negative effects on human health and the foreign environment.[citation needed]

Recycling should therefore "reduce environmental impacts of the overall product/service provision system assessed based on the life-cycle assessment approach".[90]

One study suggests that "a mandatory certification scheme for recyclers of electronic waste, in or out of Europe, would help to incentivize high-quality treatment processes and efficient material recovery".[91]

Digitalization may enable more efficient corporate processes and minimize waste.[92]

Circular business models edit

While the initial focus of the academic, industry, and policy activities was mainly focused on the development of re-X (recycling, remanufacturing, reuse, etc.) technology, it soon became clear that the technological capabilities increasingly exceed their implementation. To leverage this technology for the transition toward a circular economy, various stakeholders have to work together. This shifted attention towards business-model innovation as a key leverage for 'circular' technology adaption.[94] Rheaply, a platform that aims to scale reuse within and between organizations, is an example of a technology that focuses on asset management & disposition to support organizations transitioning to circular business models.[95]

Circular business models can be defined as business models that are closing, narrowing, slowing, intensifying, and dematerializing loops, to minimize the resource inputs into and the waste and emission leakage out of the organizational system. This comprises recycling measures (closing), efficiency improvements (narrowing), use phase extensions (slowing), a more intense use phase (intensifying), and the substitution of products by service and software solutions (dematerializing).[93] These strategies can be achieved through the purposeful design of material recovery processes and related circular supply chains.[96] As illustrated in the Figure, these five approaches to resource loops can also be seen as generic strategies or archetypes of circular business model innovation. The development of circular products, circular business models, and, more generally, the circular economy is conditioned upon the affordances of the materials involved, that is the enablement and constraints afforded by these materials to someone engaging with them for circular purposes.[97]

Circular business models, as the economic model more broadly, can have different emphases and various objectives, for example: extend the life of materials and products, where possible over multiple 'use cycles'; use a 'waste = food' approach to help recover materials, and ensure those biological materials returned to earth are benign, not toxic; retain the embedded energy, water, and other process inputs in the product and the material for as long as possible; Use systems-thinking approaches in designing solutions; regenerate or at least conserve nature and living systems; push for policies, taxes and market mechanisms that encourage product stewardship, for example 'polluter pays' regulations.[98]

Circular business models are enabled by circular supply chains. In practice, collaboration for circular supply chains can enable the creation, transfer, and/or capture of value stemming from circular business solutions. Collaboration in supply chains can extend to downstream and upstream partners, and include existing and new collaboration.[99] Similarly, circular supply chain collaboration allows innovation into the circular business model, focusing on its processes, products, or services.[100]

Digital circular economy edit

Building on circular business model innovation, digitalization and digital technologies (e.g., internet of things, big data, artificial intelligence, blockchain) are seen as a key enabler for upscaling the circular economy.[102][103][53] Also referred to as the data economy, the central role of digital technologies for accelerating the circular economy transition is emphasized within the Circular Economy Action Plan of the European Green deal. The smart circular economy framework illustrates this by establishing a link between digital technologies and sustainable resource management.[101] This allows assessment of different digital circular economy strategies with their associated level of maturity, providing guidance on how to leverage data and analytics to maximize circularity (i.e., optimizing functionality and resource intensity). Supporting this, a Strategic Research and Innovation Agenda for circular economy was published in the framework of the Horizon 2020 project CICERONE that puts digital technologies at the core of many key innovation fields (waste management, industrial symbiosis, products traceability).[104] Some researchers have emphasised a need to comply with several requirements for implementing blockchain technology in order to make circular economy a reality.[105]

Platform for Accelerating the Circular Economy (PACE) edit

In 2018, the World Economic Forum, World Resources Institute, Philips, Ellen MacArthur Foundation, United Nations Environment Programme, and over 40 other partners launched the Platform for Accelerating the Circular Economy (PACE).[106][107] PACE follows on the legacy of WEF's CEO-led initiative, Project MainStream, which sought to scale up circular economy innovations.[108] PACE's original intent has three focal areas:

- developing models of blended finance for circular economy projects, especially in developing and emerging economies;

- creating policy frameworks to address specific barriers to advancing the circular economy; and

- promoting public–private partnership for these purposes.[109][110]

In 2020, PACE released a report with partner Circle Economy claiming that the world is 8.6% circular, claiming all countries are "developing countries" given the unsustainable levels of consumption in countries with higher levels of human development.[111][112]

PACE is a coalition of CEOs and Ministers—including the leaders of global corporations like IKEA, Coca-Cola, Alphabet Inc., and DSM, governmental partners and development institutions from Denmark, The Netherlands, Finland, Rwanda, UAE, China, and beyond.[113][114] Initiatives currently managed under PACE include the Capital Equipment Coalition with Philips and numerous other partners[115][116][117] and the Global Battery Alliance with over 70 partners.[118][119] In January 2019, PACE released a report entitled "A New Circular Vision for Electronics: Time for a Global Reboot" (in support of the United Nations E-waste Coalition).[120][121]

The coalition is hosted by a Secretariat headed by David B. McGinty, former leader of the Human Development Innovation Fund and Palladium International, and board member of BoardSource.[122][123] Board Members include Inger Andersen, Frans van Houten, Ellen MacArthur, Lisa P. Jackson, and Stientje van Veldhoven.[124]

Circular economy standard BS 8001:2017 edit

To provide authoritative guidance to organizations implementing circular economy (CE) strategies, in 2017, the British Standards Institution (BSI) developed and launched the first circular economy standard "BS 8001:2017 Framework for implementing the principles of the circular economy in organizations".[125] The circular economy standard BS 8001:2017 tries to align the far-reaching ambitions of the CE with established business routines at the organizational level. It contains a comprehensive list of CE terms and definitions, describes the core CE principles, and presents a flexible management framework for implementing CE strategies in organizations. Little concrete guidance on circular economy monitoring and assessment is given, however, as there is no consensus yet on a set of central circular economy performance indicators applicable to organizations and individual products.[126]

Development of ISO/TC 323 circular economy standard edit

In 2018, the International Organization for Standardization (ISO) established a technical committee, TC 323, in the field of circular economy to develop frameworks, guidance, supporting tools, and requirements for the implementation of activities of all involved organizations, to maximize the contribution to Sustainable Development.[127] Four new ISO standards are under development and in the direct responsibility of the committee (consisting of 70 participating members and 11 observing members).[citation needed]

Strategic management in a circular economy edit

The CE does not aim at changing the profit maximization paradigm of businesses. Rather, it suggests an alternative way of thinking how to attain a sustained competitive advantage (SCA), while concurrently addressing the environmental and socio-economic concerns of the 21st century. Indeed, stepping away from linear forms of production most often leads to the development of new core competencies along the value chain and ultimately superior performance that cuts costs, improves efficiency, promote brand names, mitigate risks, develop new products,[128] and meets advanced government regulations and the expectations of green consumers. But despite the multiple examples of companies successfully embracing circular solutions across industries, and notwithstanding the wealth of opportunities that exist when a firm has clarity over what circular actions fit its unique profile and goals, CE decision-making remains a highly complex exercise with no one-size-fits-all solution. The intricacy and fuzziness of the topic is still felt by most companies (especially SMEs), which perceive circular strategies as something not applicable to them or too costly and risky to implement.[129] This concern is today confirmed by the results of ongoing monitoring studies like the Circular Readiness Assessment.[130]

Strategic management is the field of management that comes to the rescue allowing companies to carefully evaluate CE-inspired ideas, but also to take a firm apart and investigate if/how/where seeds of circularity can be found or implanted. Prior research has identified strategic development for circularity to be a challenging process for companies, demanding multiple iterative strategic cycles.[99] The book Strategic Management and the Circular Economy defined for the first time a CE strategic decision-making process,[131] covering the phases of analysis, formulation, and planning. Each phase is supported by frameworks and concepts popular in management consulting—like idea tree, value chain, VRIE, Porter's five forces, PEST, SWOT,[132] strategic clock, or the internationalization matrix—all adapted through a CE lens, hence revealing new sets of questions and considerations. Although yet to be verified, it is argued that all standard tools for strategic management can and should be calibrated and applied to a CE. A specific argument has already been made for the strategy direction matrix of product vs market and the 3 × 3 GE-McKinsey matrix to assess business strength vs industry attractiveness, the BCG matrix of market share vs industry growth rate, and Kraljic's portfolio matrix.[133]

Engineering the Circular Life cycle edit

The engineering lifecycle is a well-established approach in the design and systems engineering of complex and certified systems. It refers to the series of stages that a complex engineered product passes through, from initial concept and design through production, use, and end-of-life management. The approach is commonly used in heavy manufacturing and heavily regulated industries (for example aviation).

Complex and certified engineering systems, however, include many of the smaller products encountered on a daily basis, for example bicycles and household appliances. Implementing the principles of circularity requires all engineering design teams to take a lifecycle approach to the product.

The Circular Lifecycle for Complex Engineering Systems edit

Building on both the engineering lifecycle and the principles of the circular economy, the Circular Lifecycle for Complex Engineering Systems newly established framework, "Circular Lifecycle for Complex Engineering Systems", forms the core of this approach. This framework advocates for a reassessment of recognized engineering disciplines with an emphasis on integrating less familiar circular principles. It particularly focuses on designing to meet user needs, the application of established engineering disciplines to achieve product longevity, engineering for the transition to renewable energy sources, and maximizing value generation from waste.[134]

As with the traditional engineering lifecycle, this approach can be applied to all engineering systems, with the depth of activity tailored depending on the complexity of the product. and can incorporate multiple inter requiring planning, substantial resource consumption, and prolonged service lifetimes.

Lifecycle-Value Stream Matrix edit

The key to implementing the circular lifecycle for complex engineering systems is ensuring the engineering design team have a solid understanding of the product's ecosystem. The Lifecycle-Value Stream Matrix for complex and certified circular systems assists engineers and product design teams in visualizing the product's ecosystem more effectively. It enables engineers to map the intricate ecosystem surrounding their products, leading to the identification of potential strategic partners and novel opportunities for technology and service innovation.

The matrix captures the value stream for various suppliers, providing increasing levels of complexity in products and services. It is important to note that these suppliers will change throughout the life cycle. In the design phase of the complex engineering system, traditionally, the system-level suppliers would only be those suppliers who are integrating the engineering system itself. Later in the life cycle, the initial systems-level suppliers will be joined by other suppliers operating at a systems level, who may deliver products and services that facilitate the operation and usage of the initial engineering system.[134]

Circular Engineering Lifecycle Implementation Challenges and Opportunities edit

Adopting an engineering circular lifecycle approach undeniably brings a considerable set of challenges. Complex engineering systems, especially those with extended lifecycles and intricate safety and certification governance frameworks, may encounter difficulties while transitioning to renewable energy sources. However, the circular lifecycle concept is adaptable to a broad range of manufactured and engineered products, affirming its universal applicability.

The primary challenge within organizations will be a mindset shift and establishment of these innovative methodologies. Despite these hurdles, the implementation of this engineering lifecycle approach holds enormous potential for both consumers and businesses. This is especially true when a collaborative, through-life service approach is applied, highlighting the vast economic opportunities that can arise from embracing circularity in engineering lifecycles.[134]

Adoption and applications by industry edit

Textile industry edit

A circular economy within the textiles industry refers to the practice of clothes and fibers continually being recycled, to re-enter the economy as much as possible rather than ending up as waste.[citation needed]

A circular textile economy is in response to the current linear model of the fashion industry, "in which raw materials are extracted, manufactured into commercial goods, and then bought, used, and eventually discarded by consumers" (Business of Fashion, 2017).[135] 'Fast fashion' companies have fueled the high rates of consumption which further magnify the issues of a linear system. "The take-make-dispose model not only leads to an economic value loss of over $500 billion per year but also has numerous negative environmental and societal impacts" (Business of Fashion, 2018).[136] Such environmental effects include tons of clothing ending up in landfills and incineration, while the societal effects put human rights at risk. A documentary about the world of fashion, The True Cost (2015),[137] explained that in fast fashion, "wages, unsafe conditions, and factory disasters are all excused because of the needed jobs they create for people with no alternatives." This shows that fast fashion is harming the planet in more ways than one by running on a linear system.[citation needed]

It is argued that by following a circular economy, the textile industry can be transformed into a sustainable business. A 2017 report, "A New Textiles Economy,"[138] stated the four key ambitions needed to establish a circular economy: "phasing out substances of concern and microfiber release; transforming the way clothes are designed, sold, and used to break free from their increasingly disposable nature; radically improving recycling by transforming clothing design, collection, and reprocessing; and making effective use of resources and moving to renewable input." While it may sound like a simple task, only a handful of designers in the fashion industry have taken charge, including Patagonia, Eileen Fisher, Nathalia JMag, and Stella McCartney. An example of a circular economy within a fashion brand is Eileen Fisher's Tiny Factory, in which customers are encouraged to bring their worn clothing to be manufactured and resold. In a 2018 interview,[139] Fisher explained, "A big part of the problem with fashion is overconsumption. We need to make less and sell less. You get to use your creativity but you also get to sell more but not create more stuff."[citation needed]

Circular initiatives, such as clothing rental start-ups, are also getting more and more highlight in the EU and in the US as well. Operating with circular business model, rental services offer everyday fashion, baby wear, maternity wear for rent. The companies either offer flexible pricing in a 'pay as you rent' model like Palanta does,[140] or offer fixed monthly subscriptions such as Rent The Runway or Le Tote.[citation needed]

Another circular initiative is offering a take-back program. A company located in Colorado Circular Threads repurposes post-consumer waste materials such as old denim jeans, retired climbing rope, and discarded sails into new products, rather than letting them go to a landfill. Their take back program allows the consumer to return any product at any time so that it can be recycled again.[141]

Both China and Europe have taken the lead in pushing a circular economy. McDowall et al. 2017 stated that the "Chinese perspective on the circular economy is broad, incorporating pollution and other issues alongside waste and resource concerns, [while] Europe's conception of the circular economy has a narrower environmental scope, focusing on waste and resources and opportunities for business".[142]

Construction industry edit

The construction sector is one of the world's largest waste generators. The circular economy appears as a helpful solution to diminish the environmental impact of the industry.

Construction is very important to the economy of the European Union and its state members. It provides 18 million direct jobs and contributes to about 9% of the EU's GDP.[143] The main causes of the construction's environmental impact are found in the consumption of non-renewable resources and the generation of contaminant residues, both of which are increasing at an accelerating pace.[144] In the European Union alone, people and companies generate more than 2 billion tonnes of garbage year, or 4.8 tonnes per person, mostly from the building, mining, and manufacturing sectors.[16][145][146] Each individual in Europe generates half a tonne of municipal garbage annually, less than half of which gets recycled.[147]

Cement production accounts for 2.4% of worldwide CO2 emissions from industrial and energy sources.[148][149]

Decision making about the circular economy can be performed on the operational (connected with particular parts of the production process), tactical (connected with whole processes) and strategic (connected with the whole organization) levels. It may concern both construction companies as well as construction projects (where a construction company is one of the stakeholders).[citation needed]

End-of-life buildings can be deconstructed, hereby creating new construction elements that can be used for creating new buildings and freeing up space for new development.[150]

Modular construction systems can be useful to create new buildings in the future, and have the advantage of allowing easier deconstruction and reuse of the components afterwards (end-of-life buildings).[citation needed]

Another example that fits the idea of circular economy in the construction sector on the operational level, there can be pointed walnut husks, that belong to hard, light and natural abrasives used for example in cleaning brick surfaces. Abrasive grains are produced from crushed, cleaned and selected walnut shells. They are classified as reusable abrasives. A first attempt to measure the success of circular economy implementation was done in a construction company.[151] The circular economy can contribute to creating new posts and economic growth.[152] According to Gorecki,[153] one of such posts may be the Circular economy manager employed for construction projects.[citation needed]

Automotive industry edit

The circular economy is beginning to catch on inside the automotive industry.[154] A case study within the heavy-duty and off-road industry[77] analyses the implementation of circular practices into a lean manufacturing context, the currently dominant production strategy in automotive. Lean has continuously shown to increase efficiency by eliminating waste and focusing on customer value,[155] contributing to eco-efficiency by narrowing resource loops. However, other measures are needed to slow down and close the resource loops altogether and reach eco-effectiveness.[156] The study finds significant potentials by combining the lean and the circular approach, to not only focus on the product and process levels (eco-efficiency), but also on the system perspective (eco-effectiveness).[77] There are also incentives for carmakers to do so as a 2016 report by Accenture stated that the circular economy could redefine competitiveness in the automotive sector in terms of price, quality, and convenience and could double revenue by 2030 and lower the cost base by up to fourteen percent. So far, it has typically translated itself into using parts made from recycled materials,[157] remanufacturing of car parts and looking at the design of new cars.[158][159] Remanufacturing is currently limited to provide spare parts, where a common use is remanufacturing gearboxes, which has the potential of reducing the global warming potential (CO2-eq) by 36% compared to a newly manufactured one.[160] With the vehicle recycling industry (in the EU) only being able to recycle just 75% of the vehicle, meaning 25% is not recycled and may end up in landfills,[161] there is much to improve here. In the electric vehicle industry, disassembly robots are used to help disassemble the vehicle.[162] In the EU's ETN-Demeter project (European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles)[163] they are looking at the sustainable design issue. They are for example making designs of electric motors of which the magnets can be easily removed for recycling the rare earth metals.[citation needed]

Some car manufacturers such as Volvo are also looking at alternative ownership models (leasing from the automotive company; "Care by Volvo").[164]

Logistics industry edit

The examples and perspective in this section may not represent a worldwide view of the subject. (December 2021) |

The logistics industry plays an important role in the Dutch economy because the Netherlands is located in a specific area where the transit of commodities takes place on a daily basis. The Netherlands is an example of a country from the EU that has increasingly moved towards incorporating a circular economy given the vulnerability of the Dutch economy (as well as other EU countries) to be highly dependable on raw materials imports from countries such as China, which makes the country susceptible to the unpredictable importation costs for such primary goods.[165]

Research related to the Dutch industry shows that 25% of the Dutch companies are knowledgeable and interested in a circular economy; furthermore, this number increases to 57% for companies with more than 500 employees. Some of the areas are chemical industries, wholesale trade, industry and agriculture, forestry and fisheries because they see a potential reduction of costs when reusing, recycling and reducing raw materials imports. In addition, logistic companies can enable a connection to a circular economy by providing customers incentives to reduce costs through shipment and route optimization, as well as, offering services such as prepaid shipping labels, smart packaging, and take-back options.[165] The shift from linear flows of packaging to circular flows as encouraged by the circular economy is critical for the sustainable performance and reputation of the packaging industry.[96] The government-wide program for a circular economy is aimed at developing a circular economy in the Netherlands by 2050.[166]

Several statistics have indicated that there will be an increase in freight transport worldwide, which will affect the environmental impacts of the global warming potential causing a challenge to the logistics industry. However, the Dutch council for the Environment and Infrastructure (Dutch acronym: Rli) provided a new framework in which it suggests that the logistics industry can provide other ways to add value to the different activities in the Dutch economy. Examples of adding value in innovative ways to the Dutch economy are an exchange of resources (either waste or water flows) for production from different industries and changing the transit port to a transit hub concept. The Rli studied the role of the potentials of the logistics industry for three sectors, agriculture and food, chemical industries and high tech industries.[165]

Agriculture edit

The examples and perspective in this section may not represent a worldwide view of the subject. (October 2019) |

There has been widespread adoption of circular economic models in agriculture which is essential to global food security and to help mitigate against climate change, however there are also potential risks to human and environmental health from contaminants remaining in recycled water or organic material.[167]

These risks can be mitigated by addressing three specific issues that will also depend on the local context. These are contaminant monitoring, collection, transport, and treatment, and regulation and policy.[167]

The Netherlands, aiming to have a completely circular economy by 2050,[168] intends a shift to circular agriculture [169] as part of this plan. This shift plans on having a "sustainable and strong agriculture" by as early as 2030.[170][171] Changes in the Dutch laws and regulations will be introduced. Some key points in this plant include:

- closing the fodder-manure cycle

- reusing as much waste streams as possible (a team Reststromen will be appointed)

- reducing the use of artificial fertilizers in favor of natural manure

- providing the chance for farms within experimentation areas to deviate from law and regulations

- implementing uniform methods to measure the soil quality

- providing the opportunity to agricultural entrepreneurs to sign an agreement with the Staatsbosbeheer ("State forest management") to have it use the lands they lease for natuurinclusieve landbouw ("nature-inclusive management")

- providing initiatives to increase the earnings of farmers

Furniture industry edit

When it comes to the furniture industry, most of the products are passive durable products, and accordingly implementing strategies and business models that extend the lifetime of the products (like repairing and remanufacturing) would usually have lower environmental impacts and lower costs.[172] Companies such as GGMS are supporting a circular approach to furniture by refurbishing and reupholstering items for reuse.[173]

The EU has seen a huge potential for implementing a circular economy in the furniture sector. Currently, out of 10,000,000 tonnes of annually discarded furniture in the EU, most of it ends up in landfills or is incinerated. There is a potential increase of €4.9 billion in Gross Value Added by switching to a circular model by 2030, and 163,300 jobs could be created.[174]

A study about the status of Danish furniture companies' efforts on a circular economy states that 44% of the companies included maintenance in their business models, 22% had take-back schemes, and 56% designed furniture for recycling. The authors of the study concluded that although a circular furniture economy in Denmark is gaining momentum, furniture companies lack knowledge on how to effectively transition, and the need to change the business model could be another barrier.[175]

Another report in the UK saw a huge potential for reuse and recycling in the furniture sector. The study concluded that around 42% of the bulk waste sent to landfills annually (1.6 million tonnes) is furniture. They also found that 80% of the raw material in the production phase is waste.[citation needed]

Oil and gas industry edit

The uptake to reuse within the oil and gas industry is very poor, the opportunity to reuse is never more evident, or possible, as when the equipment is being decommissioned.[27][page needed] Hundreds of thousands of tons of waste are being brought back onshore to be recycled.[citation needed] Unfortunately, what this equates to; is equipment, which is perfectly suitable for continued use, being disposed of.[needs copy edit][176][failed verification]

In the next 30–40 years,[year needed] the oil and gas sector will have to decommission 600 installations in the UK alone. Over the next decade around 840,000 tonnes of materials will have to be recovered at an estimated cost of £25Bn. In 2017 North Sea oil and gas decommissioning became a net drain on the public purse. With UK taxpayers covering 50%–70% of the bill, there is an urgent need to discuss the most economic, social and environmentally beneficial decommissioning solutions for the general public.[177]

Organizations such as Zero Waste Scotland have conducted studies to identify areas with reuse potential, allowing equipment to continue life in other industries, or be redeployed for oil and gas.[178]

Renewable energy industry edit

Oil and gas energy resources are incompatible with the idea of a circular economy, since they are defined as "development that meets the needs of the present while compromising the ability of future generations to meet their own needs".[179] A sustainable circular economy can only be powered by renewable energies, such as wind, solar, hydropower, and geothermal.[180]

What gives entities the ability to achieve 'net zero' carbon-emissions, is that they can offset their fossil fuel consumption by removing carbon from the atmosphere. While this is a necessary first step, global smart grid technologist, Steve Hoy, believes that in order to create a circular economy we should adapt the concept of 'True Zero' as opposed to 'net zero', which is eliminating fossil fuel consumption entirely so that all energy is produced from renewable sources.[181][182]

Current growth projections in the renewable energy industry expect a significant amount of energy and raw materials to manufacture and maintain these renewable systems. "Due to the emissions attributed to fossil-fuel electricity generation, the overall carbon footprint of renewable energy technologies is significantly lower than for fossil-fuel generation over the respective systems lifespan."[183] However, there are still linear trajectories when establishing renewable energy systems that should be assessed in order to fully transition to a circular economy.[9]

Education industry edit

In 2018, The Ellen MacArthur Foundation identified 138 institutions with circular economy course offerings.[184] Since then the theme of CE topics in teaching has been incorporated at a steadily increasing pace, with plans for adoption at university, city, and country wide levels.[185][186] Zero Waste Scotland is an example of a country wide program that plans to implement CE into the Scottish education system through the "YES Circular Economy Challenge" which advocates that "every learning environment should have a whole-environment approach to learning for sustainability that is robust, demonstrable, evaluated and supported by leadership at all levels".[186] A 2021 report by the EMF compares London and New York CE course offerings and finds that there is not a "whole-environment" representation when it comes to different CE topics, with an element of the technical CE cycle being covered in 90% and element of the biological cycle covered in 50% of the 80 analyzed circular economy courses.[185] The EMF looks critically at the distribution of CE courses and researchers at Utrecht University Julian Kirchherr and Laura Piscicelli analyze the success of their introductory CE course in "Towards an Education for the Circular Economy (ECE): Five Teaching Principles and a Case Study". With 114 published definitions for the Circular Economy, synthesis and collaboration, previously exemplified, could benefit and popularize CE application in higher education.[185]

Plastic waste management edit

Laws related to recyclability, waste management, domestic materials recovery facilities, product composition, biodegradability and prevention of import/export of specific wastes may support prevention of plastic pollution.[citation needed] A study considers producer/manufacturer responsibility "a practical approach toward addressing the issue of plastic pollution", suggesting that "Existing and adopted policies, legislations, regulations, and initiatives at global, regional, and national level play a vital role".[187]

Standardization of products, especially of packaging[188][189][additional citation(s) needed] which are, as of 2022, often composed of different materials (each and across products) that are hard or currently impossible to either separate or recycle together in general or in an automated way[190][191] could support recyclability and recycling.

For instance, there are systems that can theoretically distinguish between and sort 12 types of plastics such as PET using hyperspectral imaging and algorithms developed via machine learning[192][193] while only an estimated 9% of the estimated 6.3 billion tonnes of plastic waste from the 1950s up to 2018 has been recycled (12% has been incinerated and the rest reportedly being "dumped in landfills or the natural environment").[194]

Rare-earth elements recovery edit

This section is missing information about processes to recycle/REEs that are established, demonstrated experimentally or under development as well as related policies. (March 2022) |

Potential methods edit

The rare-earth elements (REEs) are vital to modern technologies and society and are amongst the most critical elements. Despite this, typically only around 1% of REEs are recycled from end-products, with the rest deporting to waste and being removed from the materials cycle.[195] Recycling and reusing REEs play an important role in high technology fields and manufacturing environmentally friendly products all around the world.[196]

REE recycling and reuse have been increasingly focused on in recent years. The main concerns include environmental pollution during REE recycling and increasing recycling efficiency. Literature published in 2004 suggests that, along with previously established pollution mitigation, a more circular supply chain would help mitigate some of the pollution at the extraction point. This means recycling and reusing REEs that are already in use or reaching the end of their life cycle.[197] A study published in 2014 suggests a method to recycle REEs from waste nickel-metal hydride batteries, demonstrating a recovery rate of 95.16%.[198] Rare-earth elements could also be recovered from industrial wastes with practical potential to reduce environmental and health impacts from mining, waste generation, and imports if known and experimental processes are scaled up.[199][200] A study suggests that "fulfillment of the circular economy approach could reduce up to 200 times the impact in the climate change category and up to 70 times the cost due to the REE mining."[201] In most of the reported studies reviewed by a scientific review, "secondary waste is subjected to chemical and or bioleaching followed by solvent extraction processes for clean separation of REEs."[202]

Currently, people take two essential resources into consideration for the secure supply of REEs: one is to extract REEs from primary resources like mines harboring REE-bearing ores, regolith-hosted clay deposits,[203] ocean bed sediments, coal fly ash,[204] etc. A work developed a green system for recovery of REEs from coal fly ash by using citrate and oxalate who are strong organic ligand and capable of complexing or precipItating with REE.[205] The other one is from secondary resources such as electronic, industrial waste and municipal waste. E-waste contains a significant concentration of REEs, and thus is the primary option for REE recycling now[when?]. According to a study, approximately 50 million metric tons of electronic waste are dumped in landfills worldwide each year. Despite the fact that e-waste contains a significant amount of rare-earth elements (REE), only 12.5% of e-waste is currently being recycled for all metals.[206][196]

Challenges edit

For now, there are some obstacles during REE recycling and reuse. One big challenge is REE separation chemistry. Specifically, the process of isolating and refining individual rare earth elements (REE) presents a difficulty due to their similar chemical properties. In order to reduce the environmental pollution released during REE isolation and also diversify their sources, there is a clear necessity for the development of novel separation technologies that can lower the cost of large-scale REE separation and recycling.[207] In this condition, the Critical Materials Institute (CMI) under the Department of Energy has devised a technique that involves utilizing Gluconobacter bacteria to metabolize sugars, producing acids that can dissolve and separate rare-earth elements (REE) from shredded electronic waste.[208] One study suggests that by 2050, up to 40 to 75% of the EU's clean energy metal needs could come from local recycling.[209]

A study estimates losses of 61 metals, showing that use spans of, often scarce, tech-critical metals are short.[210][211] A study using Project Drawdown's modeling framework indicates that, even without considering costs or bottlenecks of expansion of renewable energy generation, metal recycling can lead to significant climate change mitigation.[212]

Chemistry edit

Researchers have developed recycling-routes for 200 industrial waste chemicals into important drugs and agrochemicals, for productive reuse that reduces disposal costs and hazards to the environment.[213][214] A study has called for new molecules and materials for products with open-environmental applications, such as pesticides, that can be neither circulated nor recycled and provides a set of guidelines on how to integrate chemistry into a circular economy.[215]

Circular developments around the world edit

Overview edit

Already since 2006, the European Union has been concerned about environmental transition issues by translating this into directives and regulations.[citation needed] Three important laws can be mentioned in this regard:[citation needed]

- The Ecodesign Framework Directive

- The Waste Framework Directive

- The Registration, Evaluation, Authorisation and Restriction of Chemicals Regulation

On 17 December 2012, the European Commission published a document entitled "Manifesto for a Resource Efficient Europe".[216]

In July 2014, a zero-waste program for Europe has been put in place aiming at the circular economy.[217] Since then, several documents on this subject have been published. The following table summarizes the various European reports and legislation on the circular economy that have been developed between 2014 and 2018.[218]

In addition to the above legislation, the EU has amended the Eco-design Working Plan to add circularity criteria and has enacted eco-design regulations with circular economy components for 7 product types (refrigerators, dishwashers, electronic displays, washing machines, welding equipment and servers and data storage products).[219] These eco-design regulations are aimed at increasing the reparability of products by improving the availability of spare parts and manuals.[219] At the same time, the European research budget related to the circular economy has increased considerably in the last few years: it has reached 964 million euros between 2018 and 2020.[218] In total, the European Union has invested 10 billion euros on Circular Economy projects between 2016 and 2019.[219]

One waste atlas aggregates some data about waste management of countries and cities, albeit the data is very limited.[220]

The "Circularity Gap Report" indicates that "out of all the minerals, biomass, fossil fuels and metals that enter the world's economy, only 8.6 percent are reused".[221][222]

The European Commission's Circular Economy Action Plan has resulted in a wide range of projects, with an emphasis on waste and material sustainability, as well as the circularity of consumer items. Despite a huge number of EU legislative measures, the European Union's circularity rate was 11.5% in 2022 and is slowing down currently.[223] [224]

Programs edit

The "Manifesto for a Resource Efficient Europe" of 2012 clearly stated that "In a world with growing pressures on resources and the environment, the EU has no choice but to go for the transition to a resource-efficient and ultimately regenerative circular economy."[216] Furthermore, the document highlighted the importance of "a systemic change in the use and recovery of resources in the economy" in ensuring future jobs and competitiveness, and outlined potential pathways to a circular economy, in innovation and investment, regulation, tackling harmful subsidies, increasing opportunities for new business models, and setting clear targets.[citation needed]

The European environmental research and innovation policy aims at supporting the transition to a circular economy in Europe, defining and driving the implementation of a transformative agenda to green the economy and the society as a whole, to achieve a truly sustainable development. Research and innovation in Europe are financially supported by the program Horizon 2020, which is also open to participation worldwide.[225] Circular economy is found to play an important role to economic growth of European Countries, highlighting the crucial role of sustainability, innovation, and investment in no-waste initiatives to promote wealth.[48]

The European Union plans for a circular economy are spearheaded by its 2018 Circular Economy Package.[226] Historically, the policy debate in Brussels mainly focused on waste management which is the second half of the cycle, and very little is said about the first half: eco-design. To draw the attention of policymakers and other stakeholders to this loophole, the Ecothis, an EU campaign was launched raising awareness about the economic and environmental consequences of not including eco-design as part of the circular economy package.[citation needed]

In 2020, the European Union released its Circular Economy Action Plan.[227]

"Closing the loop" (December 2015 – 2018) edit

This first circular economy Action Plan consisted of 54 measures to strengthen Europe's global competitiveness, promote sustainable economic growth and create more jobs.[228] Among these 54 measures, for example, is the importance of optimizing the use of raw materials, products and waste in order to create energy savings and reduce greenhouse gas emissions. The main goal being in this respect to lead to the development of a framework conducive to the circular economy.[228] In addition, the development of this Action Plan was also intended to enable the development of a new market for secondary raw materials. Concretely, here are the principal areas concerned by the Action Plan:[142]

- Production

- Consumption

- Waste Management

- Boosting markets for secondary materials

- Innovation, investment and 'horizontal' measures

- Monitoring progress

The Action plan was also a way to integrate a policy framework, an integration of existing policies and legal instruments. It includes notably some amendments.[142] As a matter of fact, the implementation of this new plan was supported by the European Economic and Social Committee (EESC). This support included in-depth consultation.[229]

Circular Economy Action Plan of 2020 edit

This new action was adopted by the European Commission in March 2020.[230] A total of 574 out of 751 MEPs voted in favour of the action plan.[231] It focuses on better management of resource-intensive industries, waste reduction, zero-carbonization and standardization of sustainable products in Europe.[230] Prior to the development of this new action plan, we can also mention the Green Deal of 2019, which integrated ecological and environmental ambitions to make Europe a carbon-neutral continent. On 10 February 2021, the European Parliament submitted its proposals to the Circular Economic Action Plan (CEAP) of the commission, highlighting five major areas in particular.[232] Those are the following:

- Batteries

- Construction and Buildings

- ICT

- Plastics

- Textiles

Two additional sectors on which the CEAP focuses could be added: packaging & food and water.[233]

Countries ranking edit

The European leaders in terms of circular economy are designated mostly by their current efforts for a shift towards circular economy but also by their objectives and the means implemented in this shift. It remains difficult to precisely rank how countries score in terms of circular economy, given the many principles and aspects of it and how differently one single country can score in each of these principles but some tendencies do appear in the average score, when combining the principles.[citation needed]

- The Netherlands: the government aims to reuse 50% of all materials as far as possible by 2030[234] and to convert waste into reusable materials anywhere it is possible. The next goal is then to make the country shift towards a 100% waste-free economy by 2050.[235] These objectives were all set from 2016 to 2019 in a series of programs for a governmental circular economy, raw materials agreements and transition agendas focusing on the five most important sectors for waste: biomass and food, plastics, manufacturing industry, construction and consumer goods.

- Germany: Germany is a leader in some aspects of circular economy, like waste management and recycling.[236]

- France is also adding several texts and measures for a better circular economy in the country such as the roadmap for circular economy in 2018, consisting of 50 measures for a successful transition to circular economy.[237]

- Belgium is also a consequent actor in the field. It scored second in the circular material use rate, before France but after the Netherlands.[238] In the other principles of circular economy, it usually scores in the top 5.[citation needed]

Other notable countries are Italy, the United Kingdom, Austria, Slovenia, and Denmark.[238]

Outside the EU, countries such as Brazil, China, Canada, the US and especially Japan are working on the shift towards it.[239]