Equations edit

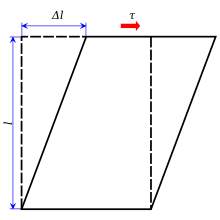

- For average shear stress

- where

- is the average shear stress,

- is the shear force applied to each section of the part, and

- is the area of the section.[1]

- Average shear stress can also be defined as the total force of as

- [2]

- Practically, the equations only give an approximation. Stress is not often equally distributed across a part so the shear strength would need to be higher to count for the estimate along with a factor of safety.

Comparisons edit

There are no published standard values for shear strength like with tensile and yield strength. Instead, it is common for it to be estimated as 60% of the ultimate tensile strength. Shear strength can be measures by a torsion test where it is equal to there torsional strength.[3][4]

- ^ Hibbeler, Russell. Mechanics of materials. ISBN 1-292-17828-0. OCLC 1014358513.

- ^ "Mechanics eBook: Shear and Bearing Stress". www.ecourses.ou.edu. Retrieved 2020-02-14.

- ^ "Shear Strength - Instron". www.instron.us. Retrieved 2020-02-14.

- ^ Portl; Portl, bolt com; Bolt; Company, Manufacturing; St, Inc 3441 NW Guam; Portl; PT547-6758, OR 97210 USA Hours: Monday-Friday 6 AM to 5 PM. "Calculating Yield & Tensile Strength". Portland Bolt. Retrieved 2020-02-14.

{{cite web}}: CS1 maint: numeric names: authors list (link)